Injection Molding Services

Zemyn Mold is a trusted leader in the injection molding industry, backed by over a decade of manufacturing experience. We specialize in helping clients reduce mold making and production costs through expert design, precision machining, and efficient processes. With advanced equipment, skilled professionals, and quick turnaround times, Zemyn Mold consistently delivers superior results that set us apart from the competition.

- 60T – 1000T injection molding machine

- Professional Quality Management Team

- Multiple materials available

What Is Injection Molding?

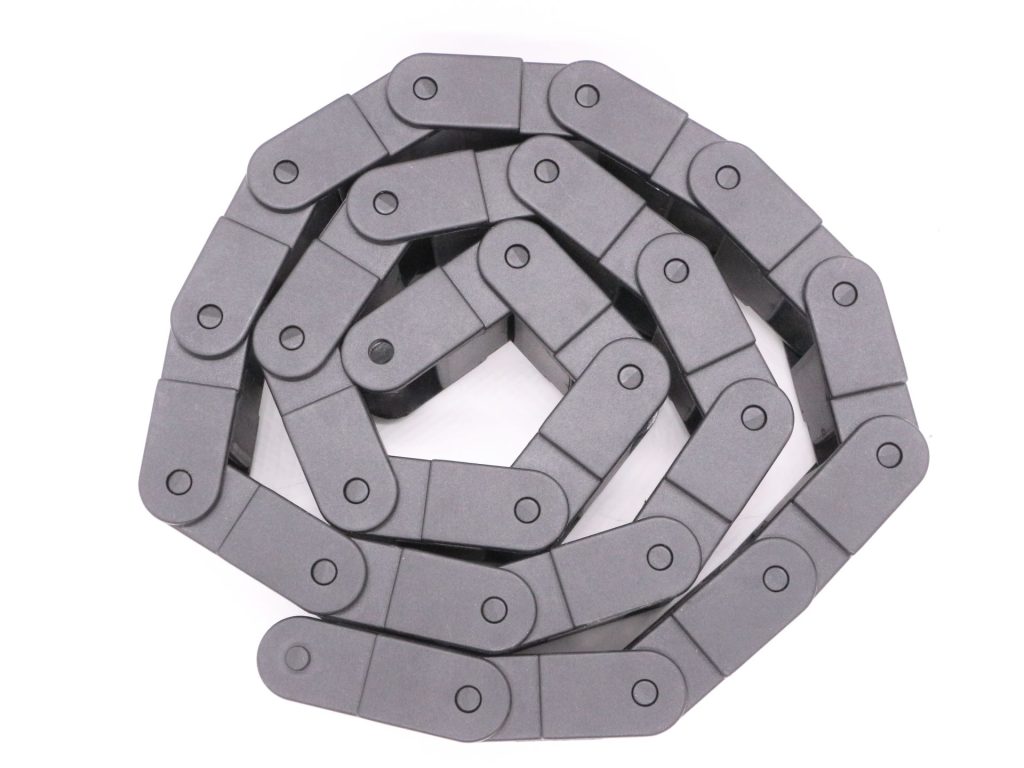

Plastic injection molding is a highly efficient manufacturing process used to produce large quantities of plastic parts. During this process, molten plastic is injected into precisely designed molds, where it cools and solidifies into the desired shape. This method is favored for its ability to produce parts with complex geometries, excellent dimensional accuracy, and consistent quality, making it ideal for mass production of plastic components across various industries.

At Zemyn, we provide high quality plastic injection molding services to meet the needs of different industries, including auto parts, electronics and consumer goods. With more than 15 years of experience, we offer end-to-end solutions from mold design and prototyping to mass manufacturing. Our advanced forming machines can handle a wide range of materials and produce parts with precise tolerances and surface finish. We offer our customers competitive prices, ensuring flexibility and cost effectiveness.

Why Choose Zemyn for Injection Molding?

Extensive Industry Experience

15+ years of professional injection molding and mold-making experience

Over 20 skilled engineers and technicians in our core team

Proven track record across 10+ industry sectors with challenging projects completed

Advanced Equipment & In-House Tooling

Equipped with five-axis machining centers, high-precision grinders, and EDM machines

Full range of injection molding machines covering various product sizes and tonnages

In-house mold design and manufacturing for fast and flexible production

Strict Quality Control

Use of CMM and NDT equipment for sampling and full product inspection

Raw material control and precise mold fitting to ensure product integrity

100% inspection before shipment, with error rate minimized at every stage

Fast, Reliable, One-Stop Service

Fast delivery with injection molded parts ready to ship in as little as 7 days

One-stop service covering mold design, molding, machining, assembly, and packaging

Professional support with tailored suggestions to meet your specific production needs